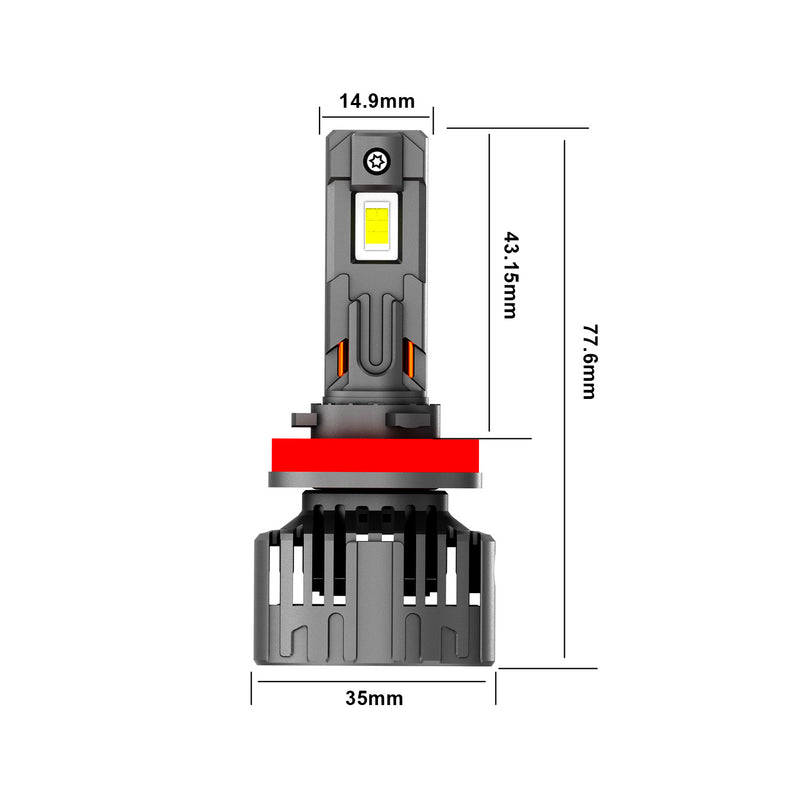

Product Specifications

|

ITEM K1C-H11 |

USAGE Headlight |

|

LED CHIP GC-7035 × 4 pcs |

COLOR TEMPERATURE 6500K ± 500K |

|

POWER OUTPUT 70 W |

ACTUAL POWER OUTPUT 68.14 W |

|

STABLE POWER OUTPUT (30 MIN) 61.68 W |

OPERATING VOLTAGE 9–36 V DC |

|

INPUT CURRENT 5.0 ± 0.5 A@13.2 V |

LUMEN OUTPUT Theoretical: 6,000 lm Actual: 5,948 lm Stable: 5,016 lm |

|

CERTIFICATION CE, RoHS |

WARRANTY 18 Months |

Wide Vehicle Compatibility K1C Series H11 LED Headlight Bulb

Universal for Cars and Trucks

K1C Series H11 is built as a practical LED headlight bulb upgrade for common H11 applications on passenger cars and light-duty trucks. The focus is broad electrical compatibility and a predictable retrofit process for workshops, distributors, and fleet users who handle different vehicle platforms. With a wide operating range of 9–36V DC, this auto light is intended to work in typical 12V and 24V environments, helping installers standardize selections and simplify inventory for everyday automotive lighting needs.

Powerful Performance

This H11 headlight bulb uses a GC-7035 LED chip platform and provides clear performance figures that reflect real operation over time. Rated power output is 70 W, with an actual power output of 68.14 W and a stable power output of 61.68 W at 30 minutes. Lumen output is also shown in a practical way: theoretical 6,000 lm, actual 5,948 lm, and stable 5,016 lm at 30 minutes. Color temperature is specified at 6500K ± 500K for a crisp white beam appearance. Input draw is listed as 5.0 ± 0.5 A@13.2V, which helps planning when this auto light is installed alone or alongside an aux light setup on the same vehicle.

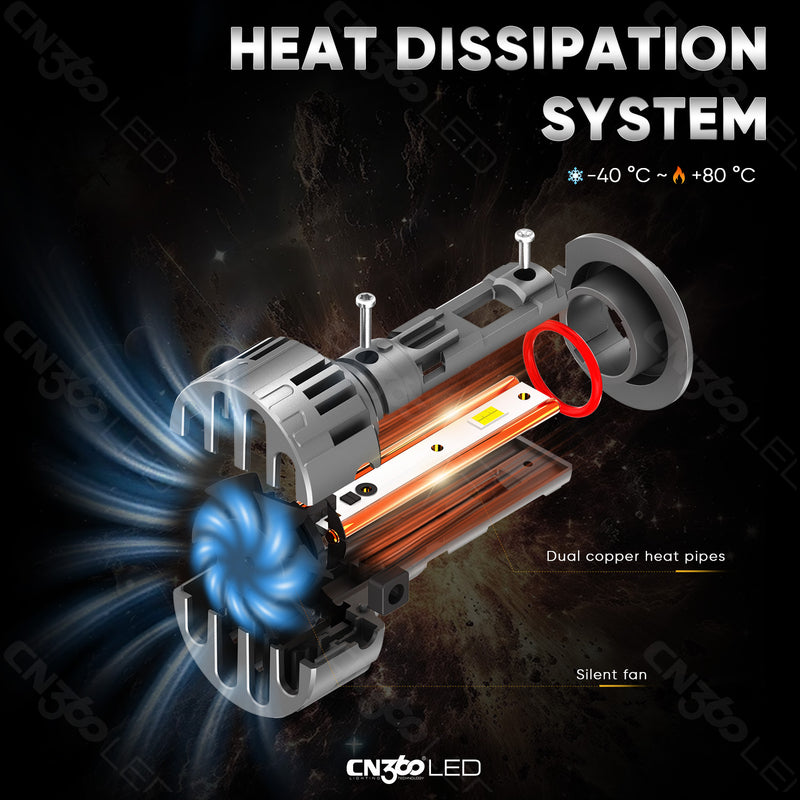

Heat Dissipation System

Thermal management is designed around a combined cooling layout featuring dual copper heat pipes and a silent fan. The heat pipes help transfer heat away from the LED heat source efficiently, while active airflow supports stable operation during extended night driving, stop-and-go traffic, or warm ambient conditions. This cooling approach helps the bulb reach a steady operating point and maintain more consistent brightness, which is essential for dependable automotive lighting performance beyond the first few minutes after start-up. The operating temperature range is specified as −40°C to +80°C, supporting everyday use across varied climates.

Integrated Die-Casting Structure

The integrated die-casting structure is built to provide rigidity and long-term stability for real vehicle duty cycles. A solid structure helps keep key components firmly positioned under vibration and temperature cycling, supporting repeatable optical alignment in the headlamp assembly. For an LED headlight bulb, that stability matters because consistent positioning helps preserve beam control and reduces the chance of unwanted stray light over time. It is a durability-focused design choice for installers who need an auto light that stays consistent after repeated heat cycles.

External Intelligent Driver

An external intelligent driver is used to regulate current delivery and support stable operation across the wide 9–36V DC input range. Separating the driver from the main bulb body helps keep sensitive electronics away from the hottest areas near the emitter, which can contribute to steadier long-run behavior. This design also provides more flexibility when routing and placing the driver in different headlamp cavities, making installation easier across vehicle platforms. For distributors and workshops, the external driver structure helps keep performance predictable in real-world automotive lighting retrofits.

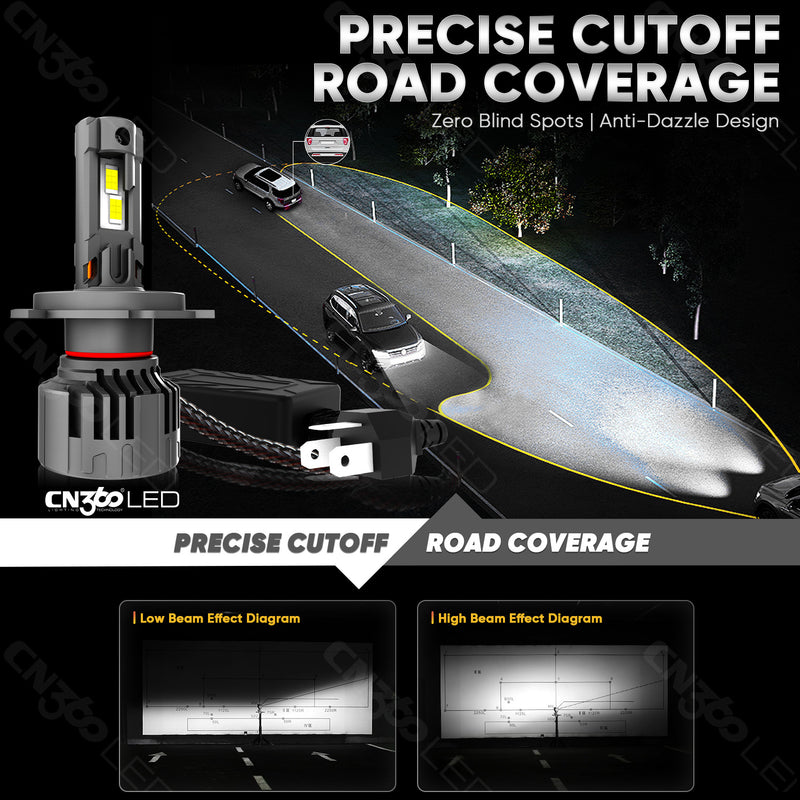

Precise Cutoff and Road Coverage

The beam concept emphasizes road-useful coverage with an anti-dazzle intent. A more controlled cutoff helps focus light where drivers need it most and reduces upward spill that can contribute to glare in mixed traffic. This approach targets a cleaner, more comfortable driving experience while maintaining practical forward coverage. When installed correctly and aimed properly, the result is an LED headlight bulb output that supports visibility without relying on scattered brightness.

Low Beam and High Beam Performance

Low beam performance is intended to keep a defined boundary and balanced foreground illumination for comfortable night driving, while high beam performance is intended to extend reach for better down-road awareness on darker routes. This combination supports real driving conditions where low beam must remain controlled around traffic and high beam must provide meaningful distance and road coverage. When paired with an aux light system, strong base headlight behavior helps keep overall automotive lighting output organized and easier to manage across different environments.

Compliance

The product lists CE and RoHS compliance, supporting common distribution requirements and documentation expectations in many markets. This helps streamline listing workflows for wholesalers and resellers who prefer recognizable compliance identification when stocking LED headlight bulb upgrades.

Built for Everyday Use

K1C Series H11 combines clear power and lumen figures with a 6500K white output target and a cooling system built around dual copper heat pipes and a silent fan. The integrated die-casting structure supports durability, while the external intelligent driver supports stable regulation across 9–36V DC vehicle electrical systems. With a beam concept focused on controlled road coverage and documented CE and RoHS compliance, this auto light is positioned for daily driving, workshop retrofits, and wholesale distribution in the automotive lighting market. Warranty coverage is listed as 18 months.