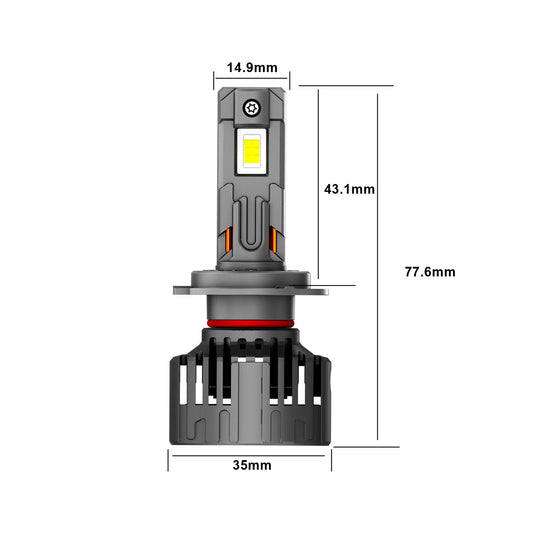

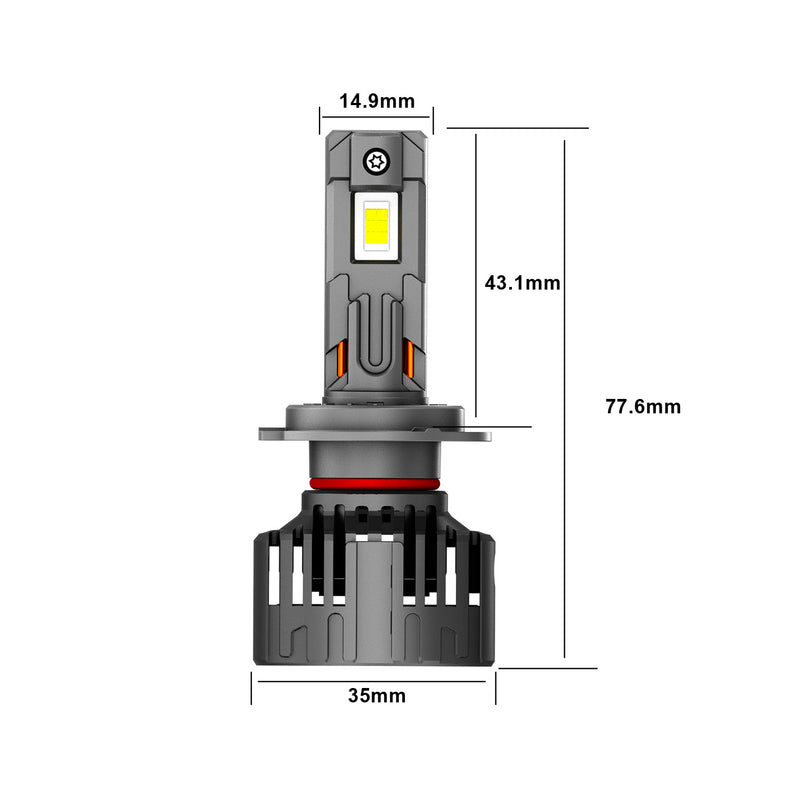

Product Specifications

|

ITEM K1C-H7 |

USAGE Headlight |

|

LED CHIP GC-7035 × 4 pcs |

BEAM ANGLE 360° |

|

OPERATING VOLTAGE DC 9–36V |

INPUT CURRENT 5±0.5A @ 13.5V |

|

POWER OUTPUT Initial: 68.14 W Stable: 61.68 W |

LUMEN OUTPUT Initial: 5948 lm Stable: 5016 lm |

|

DRIVER External intelligent driver |

POLARITY Yes |

|

ADJUSTABLE CHUCK Yes |

HEAT DISSIPATION Dual copper heat pipes + silent fan + aluminum housing |

K1C Series H7 LED Headlight Bulb for Cars and Trucks

Universal for Cars and Trucks

K1C-H7 is designed to fit a wide range of vehicles and to make alignment straightforward. An adjustable chuck allows the light source to be rotated to the correct index so the beam forms properly in both reflector and projector housings. Polarity protection reduces installation risk on vehicles where connector orientation may differ. The result is a dependable upgrade path for daily drivers, commercial fleets, and enthusiast builds alike.

Technical Data

The light engine uses four GC-7035 LEDs positioned to emulate the H7 filament location. The electrical system operates from DC 9–36 V, covering 12 V passenger platforms and 24 V commercial systems. Beam geometry is specified at 360°, supporting consistent emitter alignment once the chuck is set. Performance is expressed in two states to reflect real use: an initial value and a stable running value. Initial output reaches 5948 lm at 68.14 W, then settles to 5016 lm at 61.68 W. Input current is 5±0.5 A at 13.5 V.

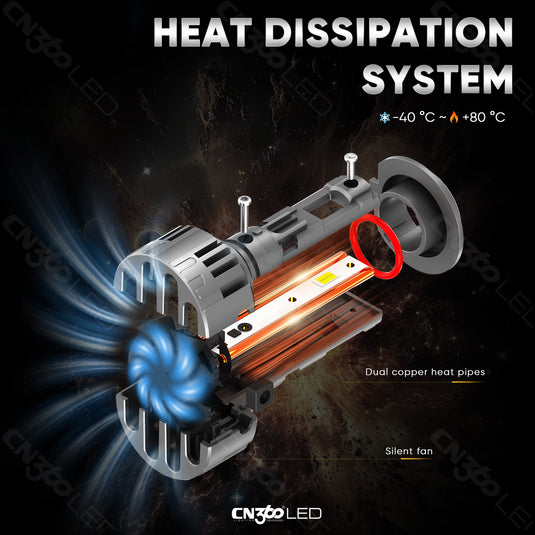

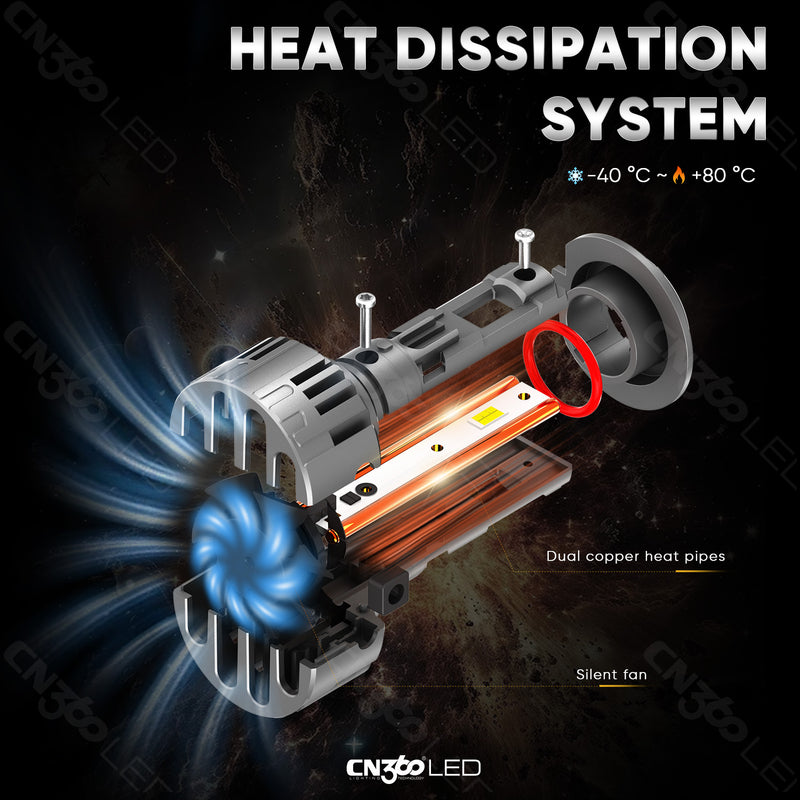

Heat Dissipation System

Effective thermal management is achieved through dual copper heat pipes that draw heat away from the LED substrate and spread it into the aluminum structure. A silent fan moves air through the heat sink to maintain low thermal resistance. This approach helps the bulb reach a steady operating point quickly and minimize lumen drop during extended night driving or high ambient temperatures, preserving visibility and component life.

Product Structure

The mechanical backbone is a robust die-cast aluminum body that supports both durability and heat capacity. High-brightness LED chips are mounted on a thermally efficient base. Power regulation is handled by an external intelligent driver, which keeps sensitive electronics out of the hot zone and delivers stable current to the LEDs. A silent fan is integrated to sustain airflow and maintain consistent output. Each element—housing, LEDs, heat pipes, fan, and external driver—works together to protect the light engine and deliver reliable performance.

External Intelligent Driver

Locating the driver outside the lamp body improves thermal balance and electrical stability. The driver regulates current to the LEDs for consistent brightness, and it assists with start-up behavior so the transition from initial to stable output is smooth and predictable. This separation also simplifies packaging inside tight headlamp cavities and reduces heat load on the LEDs themselves.

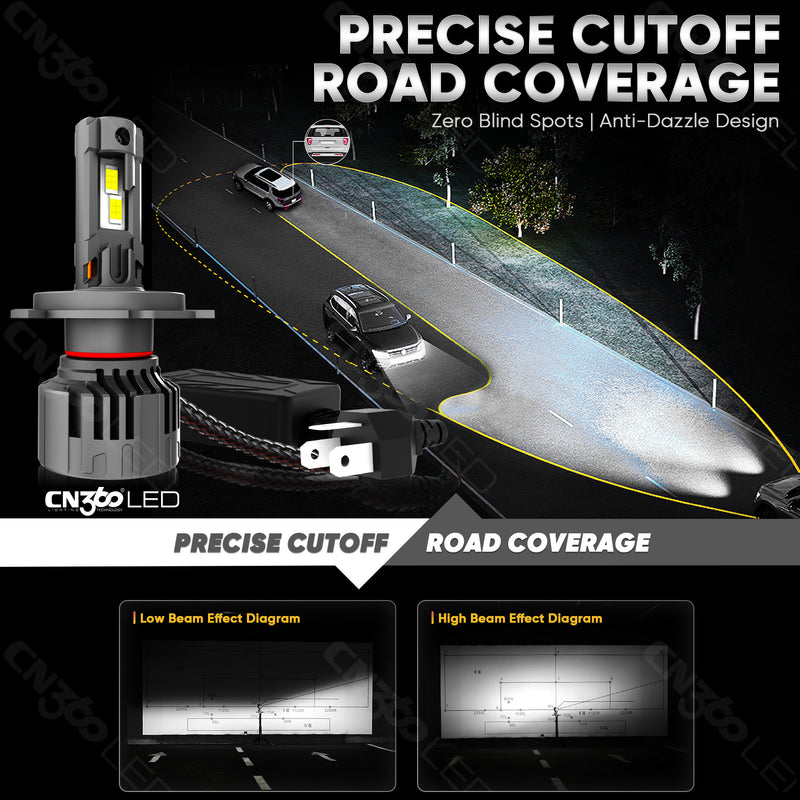

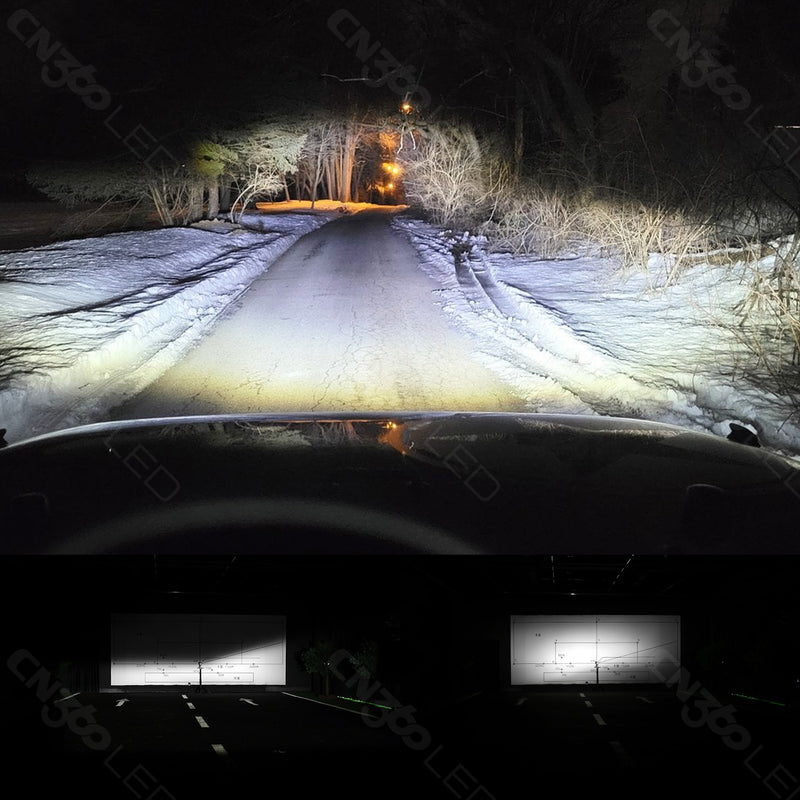

Precise Cutoff and Road Coverage

The emitter layout and indexing support a crisp low-beam cutoff and a controlled high-beam pattern. Proper aiming reduces glare to oncoming traffic while delivering strong forward reach and even foreground fill. The adjustable chuck enables fine control of emitter position so installers can dial in the beam boundary and optimize coverage without shims or additional hardware.

Low Beam and High Beam Performance

Low beam forms a sharp horizontal boundary with clear step definition for right-side illumination, improving contrast and comfort in night driving. High beam concentrates intensity down-road while maintaining adequate spread for roadside awareness. Together they provide balanced reach and width, helping drivers identify hazards earlier and maintain confidence in mixed urban and highway conditions.

Compliance

The product conforms to CE and RoHS requirements. This supports distribution into regions that require documented safety and environmental compliance and provides procurement teams with recognizable marks for acceptance and stocking.

Built for Everyday Use

K1C-H7 combines broad vehicle compatibility, transparent performance figures, and a cooling architecture that includes dual copper heat pipes, a silent fan, and an aluminum housing. The external intelligent driver stabilizes output while easing packaging inside the headlamp. With precise cutoff characteristics and controlled road coverage, the bulb offers a focused, professional lighting upgrade suitable for daily driving and fleet service.