Product Specifications

|

ITEM K1C-H3 |

USAGE Headlight |

|

LED CHIP GC-7035 |

COLOR TEMPERATURE 6500K ± 500K |

|

OPERATING VOLTAGE DC 9–36V |

INPUT CURRENT 5.0±0.5A @ 13.2V |

|

POWER OUTPUT Rated: 70 W/Bulb Initial: 66.83 W/Bulb Stable (30 min): 50.12 W/Bulb |

LUMEN OUTPUT Theoretical: 6000 lm/Bulb Initial: 6167 lm/Bulb Stable (30 min): 4730 lm/Bulb |

|

COOLING SYSTEM Dual copper heat pipes + silent fan |

DRIVER External intelligent driver |

|

STRUCTURE Integrated die casting structure |

CERTIFICATION CE, RoHS |

|

WARRANTY 18 months |

VOLTAGE COMPATIBILITY 9–36V DC |

External Intelligent Driver K1C Series H3 LED Headlight Bulb

Universal for Cars and Trucks

K1C Series H3 is positioned as a practical LED headlight upgrade for vehicles that use the H3 bulb type, covering both passenger cars and truck applications where H3 fitment is common. For distributors and workshops, a “universal for cars and trucks” concept is not only about broad vehicle categories, but about offering a consistent product option that can be stocked, recommended, and installed with predictable expectations. When a single series is meant to serve different platforms, the most important value is repeatability: the same product behavior, the same general installation logic, and a stable electrical profile that suits everyday automotive environments. This makes K1C Series H3 easier to manage as a wholesale item, especially when customers support multiple vehicle models and need a reliable specification set for procurement and replacement planning.

Powerful Performance

K1C Series H3 is specified with clear output figures that describe performance across both initial operation and stabilized running. Rated power is listed as 70 W per bulb, which defines the product’s target output class. Actual power output at initial operation is listed as 66.83 W per bulb, providing a measured reference rather than a purely nominal number. After the bulb has been running and reaches a steady working condition, stable power output at 30 minutes is listed as 50.12 W per bulb. This staged power format matters in real driving because headlight performance is often judged after warm-up, not only in the first minutes of operation.

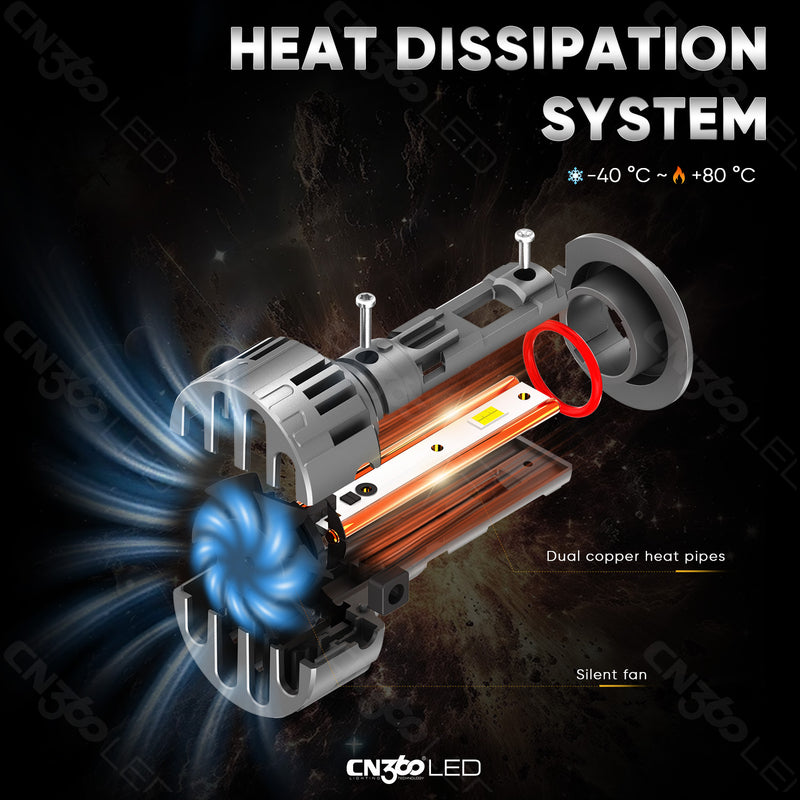

Heat Dissipation System

Heat control is a key part of LED headlight performance, especially for customers who use their vehicles for daily commuting, logistics routes, or long-distance night driving. K1C Series H3 uses a combined heat dissipation system that pairs dual copper heat pipes with a silent fan. The heat pipes are designed to transfer heat away from the LED heat source efficiently, spreading heat into the surrounding structure so that localized hotspots are reduced. Managing hotspots is important because concentrated heat can accelerate output drop and shorten stable running performance.

The silent fan supports active airflow through the heat sink area, helping the system release heat more effectively when the vehicle is idling, moving slowly, or operating in warm ambient conditions where passive cooling is less effective. The overall goal of this cooling architecture is not only to reach a strong initial output, but to help the bulb settle into a stable operating state in a controlled way. That stability aligns with the listed 30-minute stable power and stable lumen figures, which represent a more realistic long-run output point for real use.

Integrated Die-Casting Structure

The integrated die-casting structure is designed to support both durability and thermal performance in one compact assembly. A rigid metal structure helps the bulb stay stable under vibration, frequent start-stop cycles, and temperature changes that are common in normal driving and commercial duty cycles. Mechanical stability is especially important in headlight upgrades because the light source position needs to remain consistent after installation; if the emitter position shifts or the structure is not stable, the beam can become less controlled over time.

At the same time, the die-casting structure contributes to the thermal pathway by providing a solid foundation that supports heat transfer away from the LED area toward the cooling components. This is a practical approach for maintaining consistent performance during extended operation, where heat management and structural stability work together to keep output behavior predictable for end users and installers.

External Intelligent Driver

K1C Series H3 uses an external intelligent driver design to regulate power delivery and support stable operation. Keeping the driver external helps separate the control electronics from the hottest zone around the LED emitter area. This design approach can support steadier regulation during extended runtimes, because electronic components typically benefit from lower thermal stress. In real installation scenarios, an external driver can also be positioned more flexibly within the available headlamp cavity space, which helps installers manage tight packaging constraints more efficiently.

Functionally, the driver supports controlled power delivery as the bulb transitions from initial output to stable output. That matters for customers who evaluate real performance after the bulb has been running for a period of time, and it complements the staged specification format that includes both initial and 30-minute stable figures.

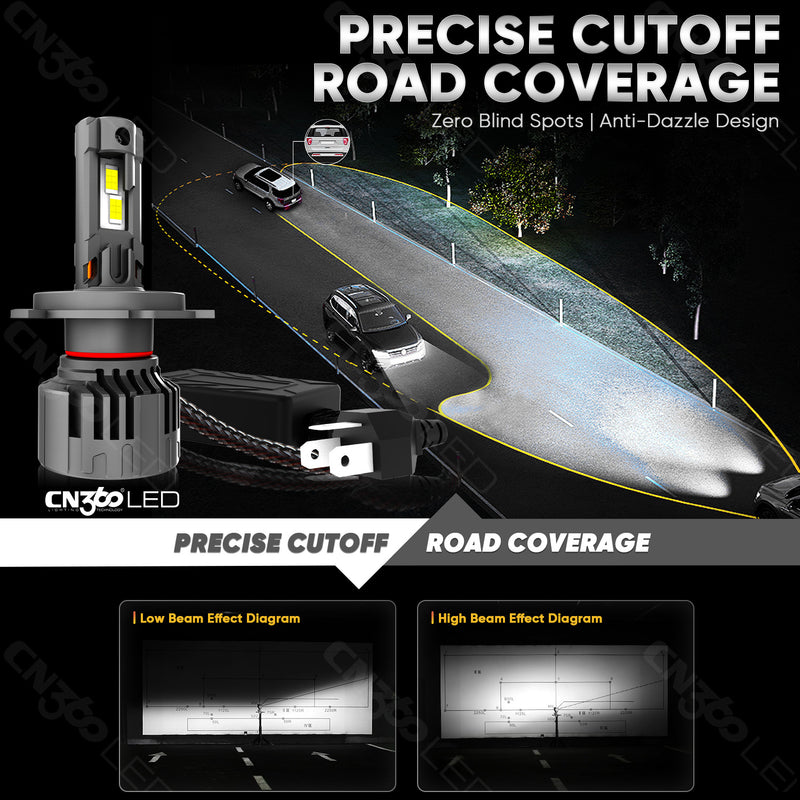

Precise Cutoff and Road Coverage

The lighting concept emphasizes precise cutoff and organized road coverage with an anti-dazzle intent. A cleaner cutoff helps keep light directed toward the road surface instead of scattering upward, which can reduce discomfort for oncoming traffic and improve overall driving comfort. In practical use, controlled road coverage is often more valuable than raw brightness because it provides a clearer, more readable illumination field across the lane and road edges.

When installed correctly and aimed properly, the beam pattern intent is to deliver visibility improvements that are usable in real driving, supporting clearer lane definition and a more stable forward field. This is particularly relevant for workshops and wholesale customers who want a product that performs consistently in customer feedback, not only something that looks bright when viewed directly.

Low Beam and High Beam Performance

Low beam and high beam performance is presented as a complete road-visibility solution concept rather than a single-mode upgrade. In low beam operation, the intent is to maintain controlled illumination with a defined boundary that supports comfortable night driving in traffic. A stable low beam pattern helps reduce glare risk and keeps the driver’s attention focused on the road surface, lane markings, and roadside conditions.

High beam performance is intended to provide stronger forward reach when driving conditions allow, supporting earlier recognition of road changes and improving reaction time on darker routes. Practical spread is also important, because drivers often need roadside awareness rather than only a narrow hotspot. With correct installation and proper headlamp aiming, the low and high beam behavior is positioned to balance control and reach across mixed driving environments.

Compliance

K1C Series H3 is listed with CE and RoHS compliance marks, supporting common documentation and distribution requirements across many markets. For B2B procurement, recognizable compliance identification can reduce friction in listing workflows and help standardize product documentation handling. This also supports resellers who need clearer compliance labeling when organizing catalog pages, preparing customer materials, or aligning with regional expectations.

Built for Everyday Use

K1C Series H3 is built around a combination of staged performance specifications and an architecture aimed at stable everyday operation. It is rated at 70 W per bulb, with 66.83 W per bulb listed for actual initial power and 50.12 W per bulb listed for stable power at 30 minutes. Lumen output is listed as 6000 lm theoretical, 6167 lm actual at initial operation, and 4730 lm stable at 30 minutes. Color temperature is rated at 6500K ± 500K, providing a consistent white output target for LED upgrade positioning.