Product Specifications

|

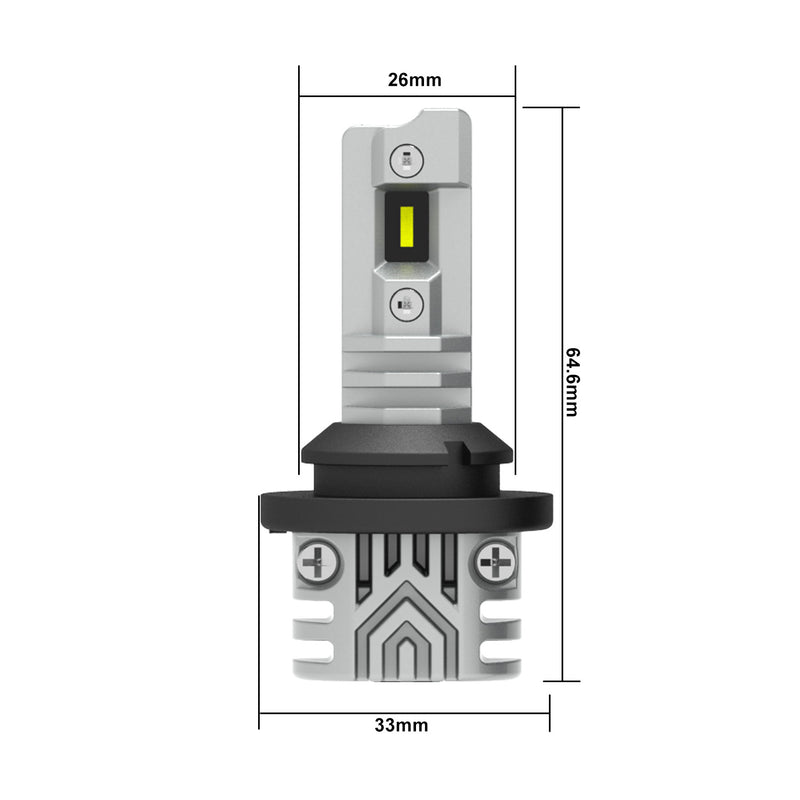

PRODUCT NAME 3A3-1156-W/O/R-150° 3A3-1156-W/O/R-180° |

THEORETICAL LUMENS 1000 LM ± 10% per bulb |

|

LED SOURCE 3 PCS 1445 customized flip chip LEDs |

ACTUAL LUMENS Approx. 1000 LM ± 10% per bulb |

|

POWER OUTPUT 13–17 W per bulb |

VOLTAGE COMPATIBILITY DC 9–18 V |

|

INPUT CURRENT 1–1.3 A @ 12 V |

COLOR OPTIONS W: white O: orange R: red |

|

BASE TYPE AND ORIENTATION 1156 single contact bayonet with 150°/180° indexing (socket angle) |

BASE TYPE 1156 single contact bayonet |

|

USAGE Back up light and rear fog light |

LIFESPAN >10,000 hours (typical) |

|

WORKING TEMPERATURE −45 °C to +85 °C |

CERTIFICATION CE and RoHS |

3A3 Series 1156 LED New Upgraded Reversing Light

The 3A3 1156 LED reversing bulbs are purpose built for rear lighting on passenger cars, SUVs, and light commercial vehicles. With high output LEDs, dedicated thermal management, and a plug and play 1156 base, they provide a clear and powerful light field whenever the vehicle is put in reverse. White, amber, and red options make the range suitable for backup lights, rear fog lights, and other rear signal positions where a compact but bright lamp is required.

Dedicated LED Bulbs for Reversing and Rear Safety

These bulbs are designed from the ground up as reversing lights rather than simple replacements for halogen filaments. The light distribution and intensity are tuned to fill the rear view camera and mirrors with clear light so that obstacles and pedestrians can be seen sooner. For vehicles that also use 1156 bulbs in rear fog or auxiliary signal positions, the same platform provides a stable light source with quick response and vivid color.

The 3A3 1156 range offers 150° and 180° bayonet orientations, so the locking pins on the base match different reflector housings. This indexing only changes the angle of the socket engagement and does not affect the beam pattern, ensuring that the lamp can be installed correctly in both original and aftermarket lamp housings.

Wide Vehicle Compatibility with Clean Electronics

The electrical design targets compatibility with more than ninety nine percent of vehicles using 1156 rear bulbs. The built in driver keeps current stable and helps the lamp work correctly with most factory wiring without triggering dashboard errors in typical applications. At the same time, the circuit is laid out to avoid electromagnetic interference so radios and other vehicle electronics continue to operate normally when the lamps are on.

High Output Light with Optimized Color

Each bulb operates on a DC 9–16V supply and draws around 1.0–1.3A in normal use, converting that power into an output of about 1600–2000 lumens. This level of brightness significantly exceeds that of standard halogen reversing bulbs, helping drivers see further behind the vehicle and making the car more noticeable to other road users.

The white version targets a cool white color around 5800K, giving a clear, neutral appearance that works well with modern LED headlights and cameras. Amber and red versions use signal colors that stand out strongly in bad weather, making them suitable for rear fog or other signaling tasks where contrast is more important than pure brightness.

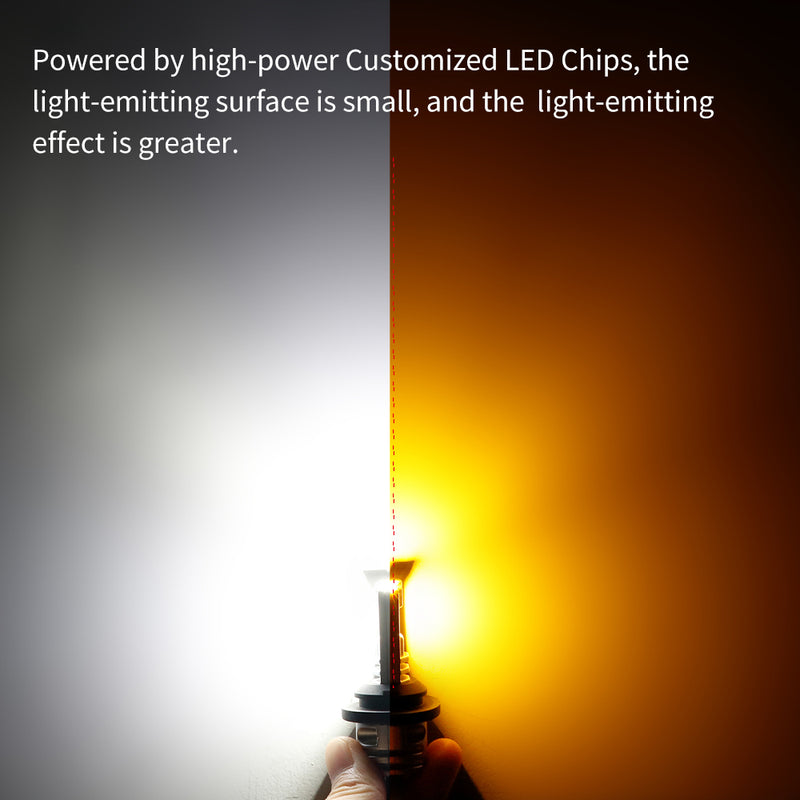

Customized High Power LED Chips

Inside each bulb, three high power 1445 LEDs provide the light source. These customized chips have a small emitting surface, concentrating the light so it can be efficiently redirected by the original reflector or lens. This design improves the effective intensity of the lamp without requiring a larger housing.

The LED layout is optimized to work with the 1156 reflector geometry, so the light fills the designated area rather than spilling into unwanted directions. This helps avoid glare to following drivers while still delivering a strong signal, especially when used as a reversing or rear fog light.

Flip Chip Packaging and Aviation Aluminum Construction

The LED modules use flip chip packaging, which mounts the chips directly to the substrate without long wire bonds. This shortens the thermal path from the LED junction to the heat sink, lowering thermal resistance and improving reliability. It also allows the light emitting surface to sit closer to the center of the reflector, which improves optical efficiency.

The structural parts of the bulb are made from aviation grade aluminum. This material quickly carries heat away from the LEDs and driver components, so the lamp can maintain high power output for longer periods without thermal fade. Compared with basic bulb constructions, the upgraded design increases usable power by more than seventy percent and can deliver up to three times the brightness of typical stock lamps under real operating conditions.

Special Silicone Lamp Head for Easy Installation

A key mechanical feature of the 3A3 1156 bulb is the silicone lamp head that surrounds the base and the neck of the housing. The silicone provides a flexible but firm interface with the lamp holder, helping to seal out dust and moisture while absorbing vibration from the road. This reduces stress on the LED assembly and contacts.

Installation remains simple and familiar. The bulb uses the standard 1156 single contact bayonet interface, so it can be installed by twisting it into the socket until it locks, with no additional wiring changes. The plug and play design means that in most cases the upgrade can be completed in minutes using only basic tools.

Durable Performance and Certified Quality

The combination of efficient thermal design and robust construction gives these bulbs a service life of more than ten thousand hours. They are specified to operate in ambient temperatures from -45°C to +85°C, making them suitable for both very cold and very hot climates where conventional bulbs often fail prematurely.

Quality is supported by compliance with CE and RoHS requirements, covering both safety and environmental aspects. For fleet users and professional installers, this means the 3A3 1156 LED reversing bulbs offer a dependable solution with reduced maintenance and consistent performance across a wide range of vehicles and applications.