Product Specifications

|

ITEM K1C-H1 |

USAGE Headlight |

|

LED CHIP GC-7035 × 4 pcs |

OPERATING VOLTAGE DC 9–36V |

|

INPUT CURRENT 5.0±0.5A @ 13.2V |

COLOR TEMPERATURE 6500K ± 500K |

|

POWER OUTPUT Rated: 70 W Initial: 66.83 W Stable: 50.12 W |

LUMEN OUTPUT Theoretical: 6000 lm Initial: 6167 lm Stable: 4730 lm |

|

DRIVER External intelligent driver |

COOLING SYSTEM Dual copper heat pipes + silent fan |

|

STRUCTURE Integrated die casting structure |

CERTIFICATION CE, RoHS |

|

WARRANTY 18 months |

VOLTAGE COMPATIBILITY 9–36V DC |

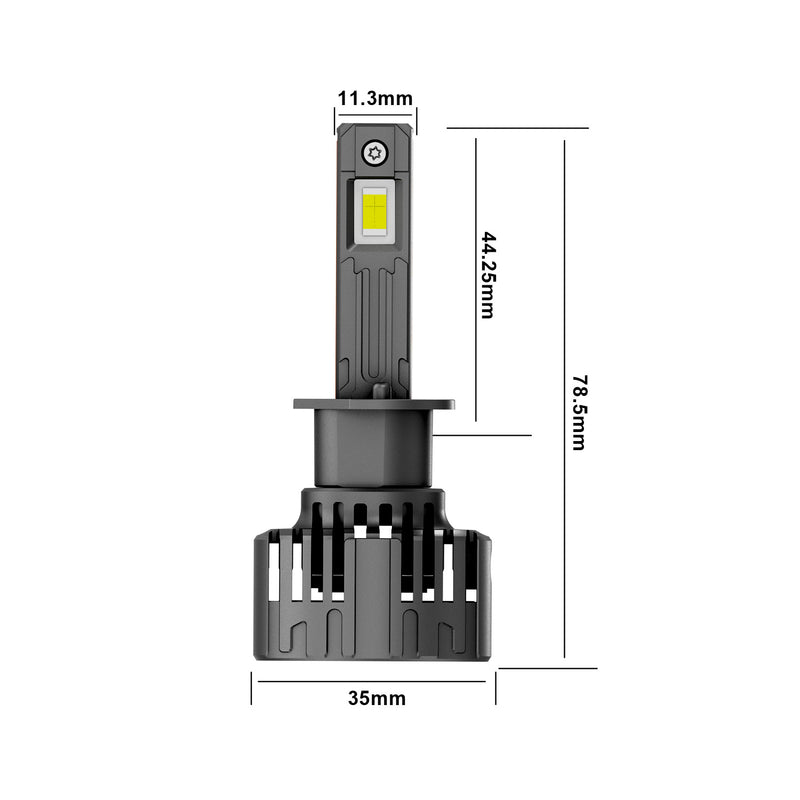

Integrated Die Casting Structure K1C Series H1 LED Headlight Bulb

Universal for Cars and Trucks

K1C Series H1 is built for common H1 headlight applications across both passenger cars and trucks, making it a practical choice for workshops, distributors, and fleet users who need one series that can cover a wide range of vehicles. In wholesale and service scenarios, “universal” means stable fitment logic and predictable performance expectations across multiple platforms. This approach helps reduce SKU complexity and supports more consistent installation outcomes when the same product needs to be used across different vehicle models and usage conditions.

Powerful Performance

The H1 version uses a four-chip GC-7035 LED configuration and is specified with staged performance figures that reflect real operating behavior. Rated power is 70W. Actual measured power is listed as 66.83W at initial operation, while stable power at 30 minutes is listed as 50.12W. Presenting both initial and stabilized power helps set accurate expectations for long-duration driving where thermal equilibrium becomes the deciding factor for sustained output.

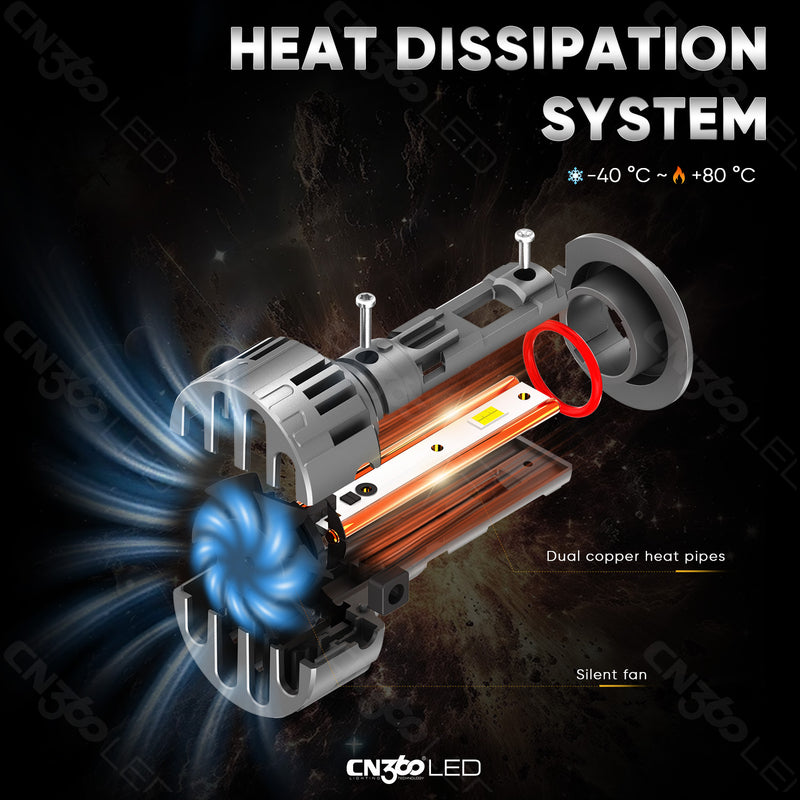

Heat Dissipation System

Thermal management is engineered around a combined cooling architecture that includes dual copper heat pipes and a silent fan. The copper heat pipes are designed to move heat away from the LED heat source efficiently and distribute it through the heat sink structure. By reducing concentrated hot spots, the system supports a more stable operating point and helps the bulb maintain usable brightness during extended driving rather than only delivering a short peak at startup.

Active airflow is supported by a silent fan, which helps push air through the heat sink area. This airflow becomes especially important in slow driving, stop-and-go traffic, and warmer ambient conditions where passive cooling is less effective. The combined approach is intended to support long run-times with more consistent light output, aligning with the listed stable power and stable lumen specifications at 30 minutes.

Integrated Die-Casting Structure

The bulb assembly is built around an integrated die-casting structure that emphasizes strength and stability for real automotive use. A rigid metal structure helps the product stay mechanically stable under vibration and repeated temperature cycling, which are common in daily driving and fleet operation. This integrated body also works as part of the thermal pathway, supporting heat transfer away from the LED area into the cooling components.

For installation consistency, a stable, fixed structure helps keep the light source position reliable once installed. In headlight optics, small variations in emitter position can influence beam formation, so the structure’s stability supports more predictable results for workshops that need repeatable outcomes across multiple vehicles and multiple installs.

External Intelligent Driver

K1C Series H1 uses an external intelligent driver design to support regulated power delivery. Keeping the driver external helps separate sensitive electronics from the hottest zone behind the LED emitter area, which can support steadier operation during extended use. This layout can also offer practical flexibility during installation because the driver can be positioned where space allows in the headlamp cavity instead of being confined to the tightest area directly behind the bulb.

In operation, the driver’s role is to maintain stable current control and support predictable performance as the bulb transitions from initial output to its stabilized running condition. This is aligned with the product’s specification format that clearly distinguishes initial and stable power and lumen figures, reflecting how the bulb is expected to behave once heat and operating conditions settle.

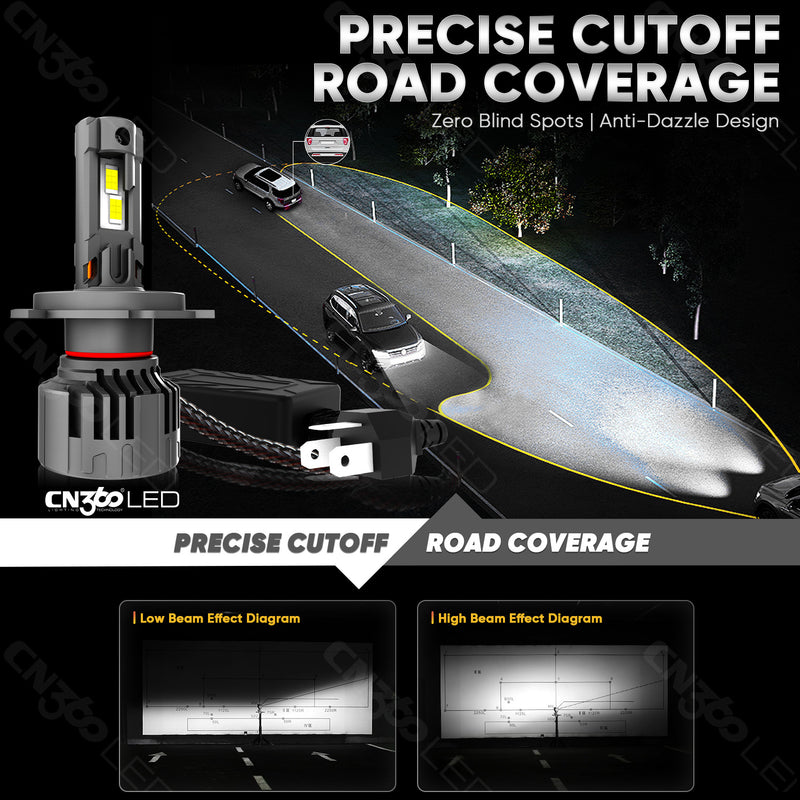

Precise Cutoff and Road Coverage

The beam concept emphasizes precise cutoff and road coverage with an anti-dazzle intent. A cleaner cutoff helps keep light focused on the usable road surface while reducing stray upward spill that can contribute to glare for oncoming traffic. For drivers, controlled distribution supports clearer lane-edge visibility and a more organized illumination field, which can reduce visual fatigue during longer night drives.

Road coverage is positioned as practical and directional rather than scattered. When installed correctly and aimed properly, the light pattern is intended to deliver visibility improvements that feel usable in real driving, not only “bright” in appearance. This is especially important for professional installers and B2B customers who want repeatable performance that looks controlled in front of the vehicle.

Low Beam and High Beam Performance

The product positioning includes low beam and high beam performance as a combined road-visibility concept. In low beam, the intent is to deliver controlled illumination with a defined boundary so drivers can maintain comfort and reduce unwanted glare in traffic. Organized foreground lighting helps the road surface remain readable, supporting everyday commuting and mixed-traffic driving where low beam is used most of the time.

High beam is intended to provide stronger down-road reach when road conditions allow. The goal is to extend visibility farther ahead so drivers can identify road changes earlier, especially on darker routes. At the same time, practical spread supports roadside awareness rather than a narrow, overly concentrated hotspot. With correct installation and proper headlamp aiming, low and high beam behavior is designed to balance control and reach across real driving situations.

Compliance

K1C Series H1 is listed with CE and RoHS compliance marks. These identifiers support common distribution and documentation requirements in many markets and can simplify listing, procurement, and stocking processes for wholesalers and resellers. For B2B buyers, recognizable compliance labeling can also help reduce friction when preparing product pages, handling customer documentation requests, or organizing inventory across multiple regions.

Built for Everyday Use

K1C Series H1 combines staged performance figures with a 6500K white output target and a cooling system designed for sustained operation. Rated power is 70W, with an initial measured power of 66.83W and a stable 30-minute power of 50.12W. Lumen output is listed as 6000 lm theoretical, 6167 lm actual at initial operation, and 4730 lm stable at 30 minutes. Wide voltage compatibility at DC 9–36V and a listed input current of 5.0±0.5A at 13.2V support typical automotive electrical environments across cars and trucks.

By combining dual copper heat pipes, a silent fan, an integrated die-casting structure, and an external intelligent driver, the product is positioned to deliver practical, consistent headlight performance for daily driving and professional installation. With controlled road coverage intent and CE and RoHS compliance, it fits the needs of wholesale supply, workshop retrofits, and fleet maintenance programs. The warranty is listed as 18 months, supporting regular use expectations in both personal and professional vehicle applications.